The intersection of Artificial Intelligence (AI) and Product Lifecycle Management (PLM) is revolutionizing how organizations design, develop, and deliver products. With AI-driven enhancements, PLM systems are shifting from reactive to proactive tools that empower innovation, speed, and efficiency. Let’s explore how integrating AI transforms PLM compared to traditional methods.

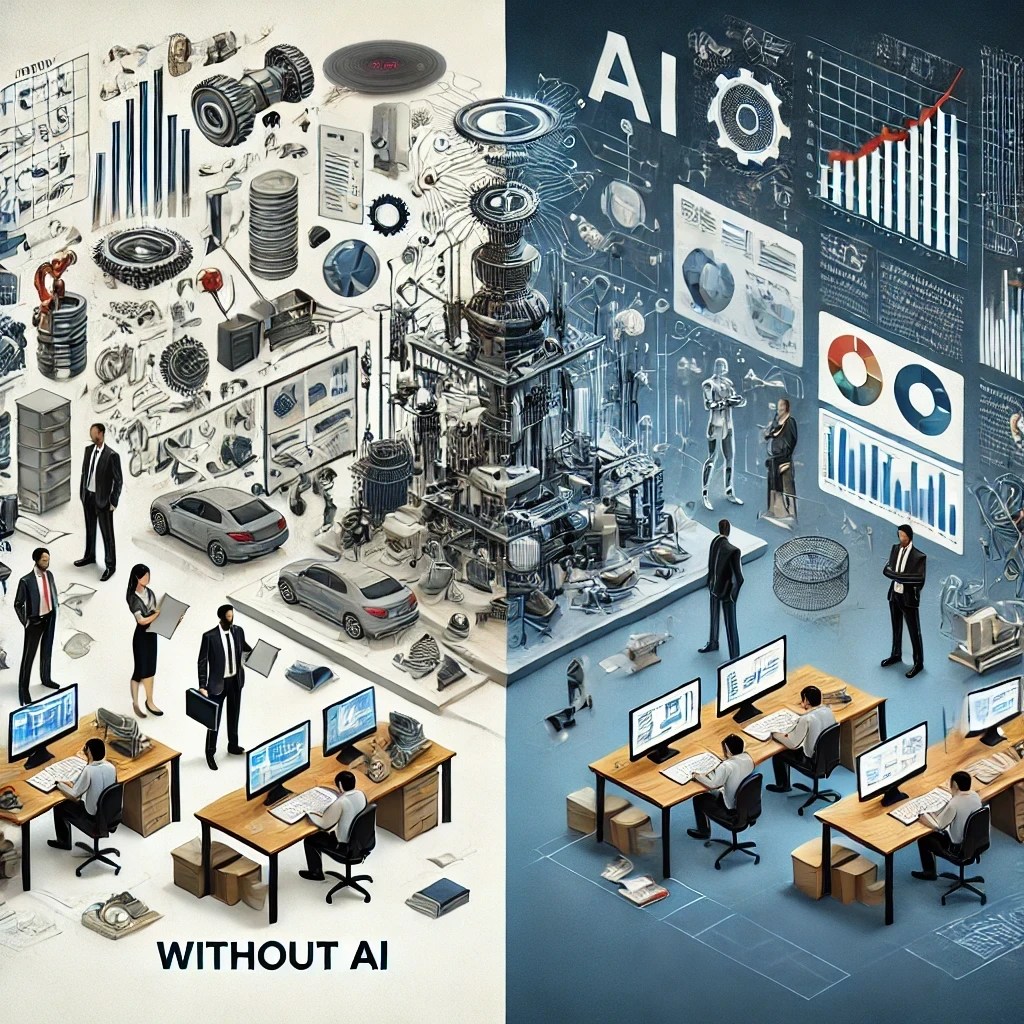

Key Differences: With AI vs. Without AI in PLM Systems

| Feature/Aspect | PLM Without AI | PLM With AI |

|---|---|---|

| Data Management | Relies on manual input and predefined rules. | Uses machine learning to analyze and process vast amounts of data automatically. |

| Collaboration | Static collaboration through traditional tools. | Dynamic collaboration enhanced by AI-driven insights and recommendations. |

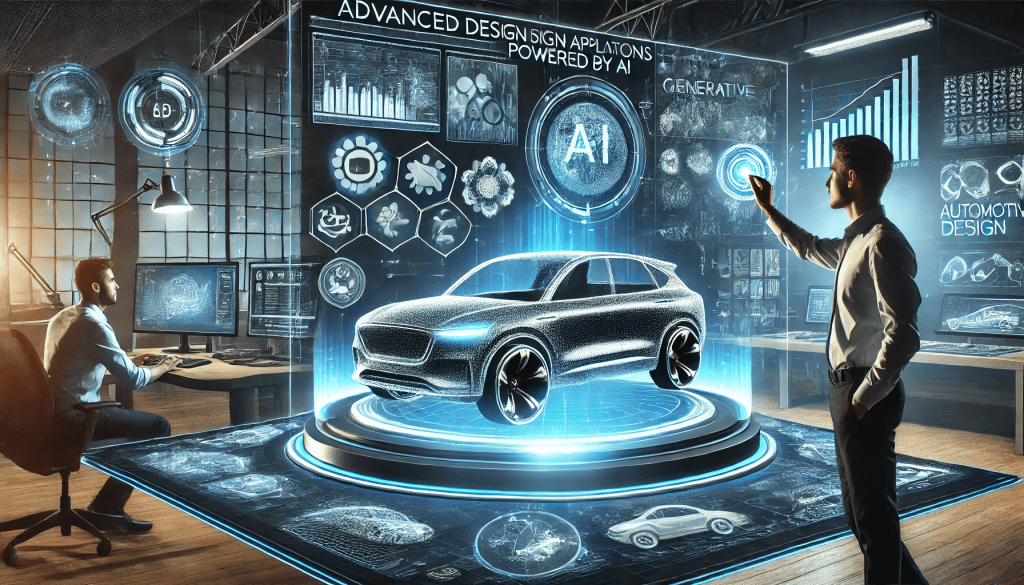

| Product Design Optimization | Iterative and dependent on human expertise. | Predictive modeling and optimization using AI algorithms. |

| Time-to-Market | Longer due to manual planning and execution. | Shortened through automated processes and predictive analytics. |

| Error Detection | Errors often discovered late in the lifecycle. | AI proactively detects potential errors in design or production early. |

| Customization | Limited, often generalized for larger groups. | Hyper-personalization based on real-time data and AI insights. |

| Cost Management | Difficult to predict and control throughout lifecycle. | AI-driven cost predictions and resource optimization minimize overspending. |

| Supply Chain Coordination | Reactive and siloed operations. | Proactive, real-time coordination using AI to address disruptions. |

| Regulatory Compliance | Manual and error-prone. | Automated compliance checks based on regulations and standards. |

| Customer Feedback Analysis | Relies on surveys and manual input. | AI-powered sentiment analysis and real-time feedback integration. |

Leave a comment