Welding and fabrication have long been the backbone of modern manufacturing—fusing materials, shaping components, and building everything from surgical instruments to skyscrapers. But a quiet revolution is unfolding: Artificial Intelligence (AI) is entering the shop floor, bringing intelligence to heat, precision to sparks, and scalability to craftsmanship.

Today, we explore how AI is reshaping the future of Capacitor Discharge Welding (CDW), Laser Welding, Custom Fabrication, and Cost-Efficient Production.

🔍 What’s Happening in the Welding & Fabrication Industry?

Despite the rise of automation, welding and fabrication still face persistent challenges:

- Precision under pressure: High-spec industries demand sub-millimeter accuracy.

- Skilled labor shortages: Seasoned welders are retiring faster than new ones can be trained.

- Complex customization: One-off parts and prototypes slow down traditional workflows.

- Cost-efficiency pressures: Rising raw material and energy costs demand leaner operations.

Enter AI—ready to optimize, predict, automate, and elevate.

⚡ Capacitor Discharge Welding (CDW) + AI

CDW is a rapid welding method where electrical energy is discharged in milliseconds to weld studs or pins to a base material—common in HVAC and automotive.

🧠 How AI Can Help:

- Process Monitoring: AI can use real-time sensor data (current, voltage, pressure) to detect misfires, weak bonds, or surface contamination.

- Predictive Maintenance: Machine learning models can forecast part/tool failures before they interrupt production.

- Parameter Optimization: AI can adjust energy and pressure settings based on material type and surface condition, reducing trial-and-error setups.

📈 Result: Increased weld quality, reduced downtime, and fewer defective parts.

🔬 Laser Welding + AI

Laser welding is prized for precision and minimal thermal distortion, widely used in aerospace, medical devices, and high-end manufacturing.

🧠 How AI Can Help:

- Vision Systems with Deep Learning: Cameras + AI detect joint gaps, focus issues, or material inconsistencies—adjusting in real time.

- Adaptive Control: AI can adjust beam focus, speed, and trajectory dynamically based on weld pool feedback.

- Defect Detection: AI-powered image recognition flags porosity, underfill, or cracks instantly—sometimes better than human inspectors.

📈 Result: Near-zero defect rates and scalability for high-spec industries.

🧰 Custom Fabrication + AI

Custom fabrication involves non-standard parts, one-off builds, or low-volume production, often with tight deadlines and variable designs.

🧠 How AI Can Help:

- AI-Driven CAD-to-CAM Automation: AI can speed up design-to-manufacture transitions by auto-generating toolpaths and material usage plans.

- Generative Design: AI can create lightweight, optimized structures that meet strength and tolerance needs—reducing waste and cost.

- Intelligent Quoting: Machine learning predicts job costs and timelines based on historical data, material complexity, and tooling needs.

📈 Result: Faster quotes, smarter designs, and more agile operations.

💰 Cost-Effective Production + AI

Reducing cost without compromising quality is the ultimate goal.

🧠 How AI Can Help:

- Process Optimization: AI can identify bottlenecks across welding and fabrication lines, suggesting layout or workflow changes.

- Energy Consumption Tracking: AI systems can monitor power usage across equipment to reduce energy waste—critical in high-power laser and CDW systems.

- Supply Chain Intelligence: AI can recommend inventory levels and reorder timing, avoiding delays and overstocking.

📈 Result: Leaner, smarter, and more profitable production systems.

🔮 Future Outlook: Where AI is Heading

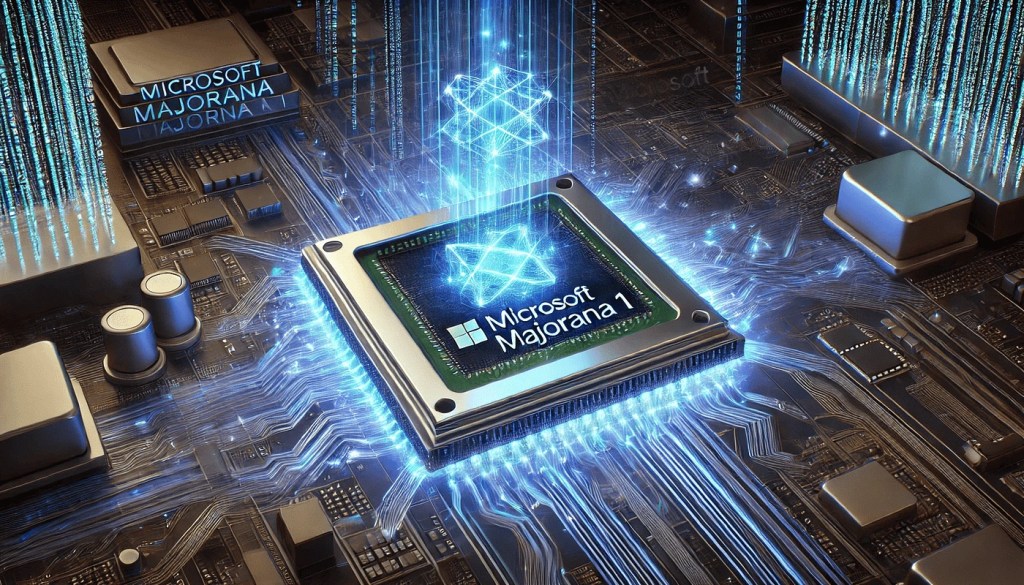

- AI Co-Pilots for Welders: Augmented reality + AI guiding human welders with overlay instructions.

- Self-Correcting Robots: Autonomous welding arms using reinforcement learning to improve over time.

- Digital Twins: Virtual replicas of fabrication cells for simulation, optimization, and predictive planning.

🏁 Final Thoughts

Welding and fabrication aren’t just about heat and hammers anymore. They’re becoming smart, connected, and autonomous. For companies leveraging CDW, laser welding, and custom fabrication, AI offers a clear edge: better quality, faster turnaround, and lower costs.

The fusion of fire and intelligence is here—and it’s building the future.

Leave a comment