In 2025, inventory management isn’t just a backend process—it’s become a frontline strategic function. It’s where profitability, agility, and customer satisfaction converge. But as businesses face rising global uncertainty, unpredictable demand, and increasingly complex sales channels, managing inventory has never been more challenging—or more critical.

This article breaks down the top challenges in modern inventory management and explores how Artificial Intelligence (AI) is solving them in real-time.

📉 Current Challenges in Inventory Management

Whether you’re a startup or a global retailer, inventory pain points are everywhere. Here’s what companies are struggling with:

| Challenge | Description |

|---|---|

| Supply Chain Disruptions | Caused by global instability, logistics delays, or unreliable suppliers. |

| Demand Volatility | Rapid shifts in consumer behavior, seasonality, and macroeconomic trends. |

| Lack of Real-Time Data | Reliance on manual or outdated systems creates blind spots and delays. |

| Omnichannel Complexity | Difficulty syncing inventory across stores, websites, apps, and third-party marketplaces. |

| High Holding Costs | Excess inventory ties up capital, takes up space, and risks obsolescence. |

| Fragmented Tech Systems | Disconnected ERP, POS, and WMS systems hinder seamless data flow. |

| Sustainability Pressure | Increased demand to reduce waste and improve environmental responsibility. |

| Labor Shortages | Difficulty finding and retaining skilled inventory and supply chain workers. |

🤖 AI-Powered Solutions: The Future of Inventory Management

AI isn’t just a thing of the future — it’s being used today to tackle real problems. Here’s how companies are using AI to transform the way they manage inventory:

| AI Solution Area | What AI Enables | Benefit to Business |

|---|---|---|

| Predictive Analytics | Analyzes supplier behavior, lead times, and global events. | Helps anticipate risks and reduce disruption. |

| Demand Forecasting | Uses machine learning to analyze sales trends, seasonality, and external data. | Delivers precision in planning, reducing stockouts and excess. |

| Real-Time Inventory Tracking | Integrates AI with IoT sensors and computer vision to provide live inventory status. | Enables immediate action and reduces manual errors. |

| Omnichannel Optimization | Dynamically reallocates inventory based on real-time demand across all channels. | Boosts fulfillment speed and customer satisfaction. |

| Smart Reordering Algorithms | Automatically adjusts reorder levels using demand forecasts and supply lead times. | Improves cash flow and lowers warehouse costs. |

| AI Integration Layers | Acts as intelligent middleware over ERP, POS, and WMS systems. | Reduces tech friction and enables automation without costly infrastructure changes. |

| Inventory Waste Minimization | Optimizes product lifecycle to reduce spoilage and unsold inventory. | Supports ESG goals and waste reduction. |

| Robotics & AI Assistants | Augments human workers with warehouse automation and smart agents. | Enhances team productivity and enables smarter resource allocation. |

🏪 Case in Focus: Walmart’s AI Advantage

Walmart has emerged as a global leader in AI-driven inventory management. Here’s how they do it:

- Computer Vision: Cameras and sensors monitor shelves, alerting staff when items are out of stock.

- AI Forecasting: Predicts demand using millions of data points, including weather, promotions, and local events.

- Automated Replenishment: Orders are placed automatically based on real-time insights and customer demand.

The result: Reduced stockouts, streamlined warehouse operations, and consistently high customer satisfaction—powered entirely by AI.

🔗 Read more:

Walmart reveals plans to scale AI, AR, and immersive tech for retail – Walmart Newsroom

AI @ Walmart – Walmart Global Tech

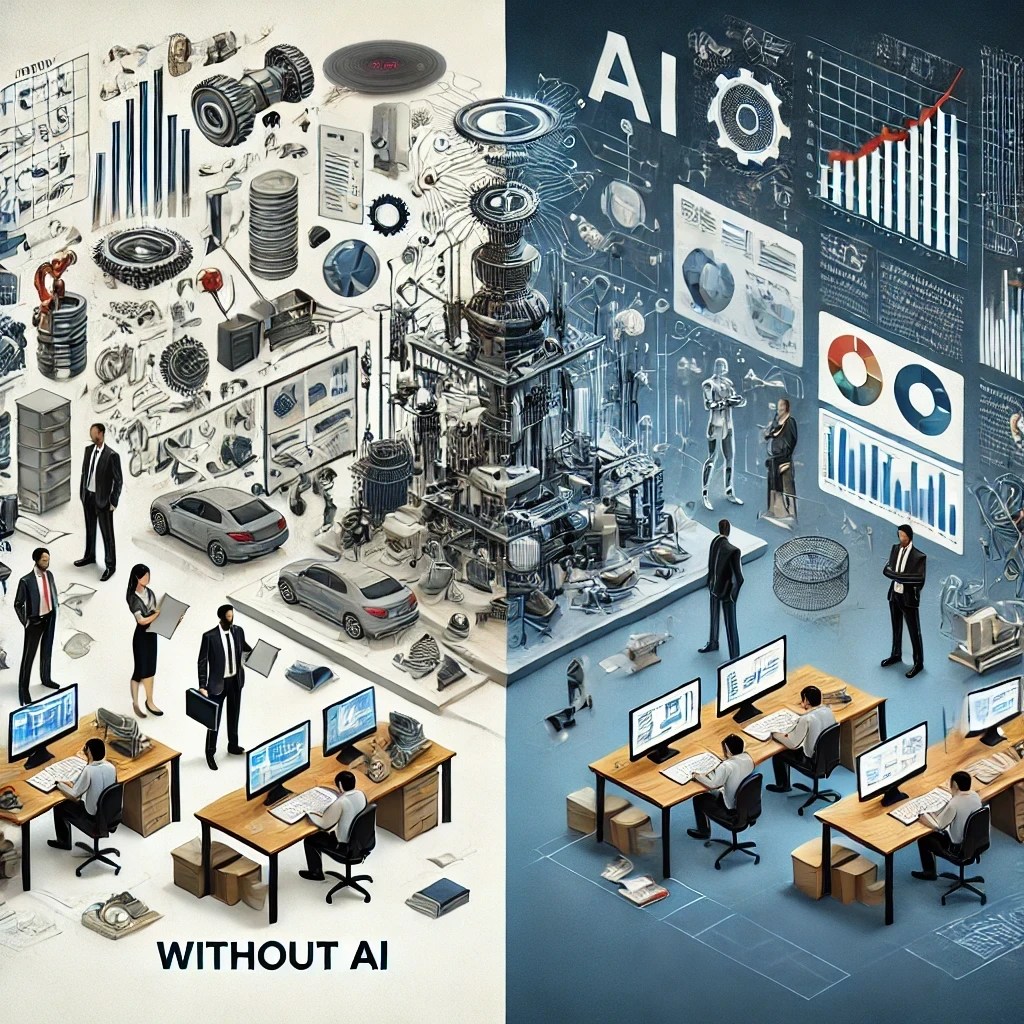

📊 Traditional vs AI Inventory Management

| Capability | Traditional Systems | AI-Enhanced Systems |

|---|---|---|

| Forecast Accuracy | Based only on past sales data | Learns from real-time and external signals |

| Replenishment | Manual or fixed thresholds | Predictive, adaptive, and self-tuning |

| Data Integration | Siloed ERP/POS/WMS systems | Unified via smart AI integration layers |

| Waste Management | Reactive and late-stage | Proactive and aligned with sustainability goals |

| Workforce Support | Manual-heavy operations | Augmented with robotics and AI agents |

💼 Why It Matters for Business Leaders

Inventory is no longer just an operational concern—it’s a strategic lever. Here’s why leaders are investing in AI:

| Focus Area | Why It Matters |

|---|---|

| Strategy | Inventory drives growth, agility, and market responsiveness. |

| Customer Experience | AI delivers faster, more reliable product availability. |

| Competitive Advantage | Early AI adopters are optimizing faster, cheaper, and more intelligently. |

| Cost Efficiency | AI reduces waste, labor costs, and capital tied in stock. |

| Sustainability | Smart inventory reduces waste and aligns with ESG and brand goals. |

✅ Final Thoughts

As global commerce grows more complex, the companies that win will be those that master intelligent inventory management. AI is no longer optional — it’s the engine that drives agility, efficiency, and resilience in the modern supply chain.

Whether you’re a logistics manager, CFO, or founder, investing in AI for inventory is an investment in your company’s ability to predict, adapt, and thrive.

Leave a comment